ball milling and production and pdf and concrete

2022-02-02T22:02:32+00:00

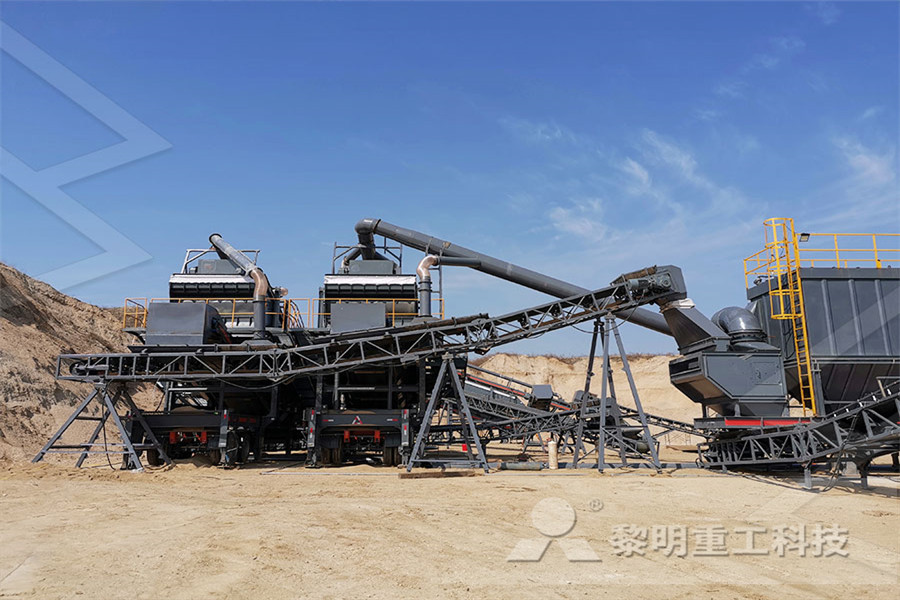

BALL MILLS Ball mill optimisation holzinger

2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can 2012年6月1日 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding (PDF) Grinding in Ball Mills: Modeling and Process 2021年4月27日 Ball mills have been the traditional method of comminution in the mineral processing industries and continue to operate with old generation classifiers, their OPTIMIZATION OF CEMENT GRINDING OPERATION IN

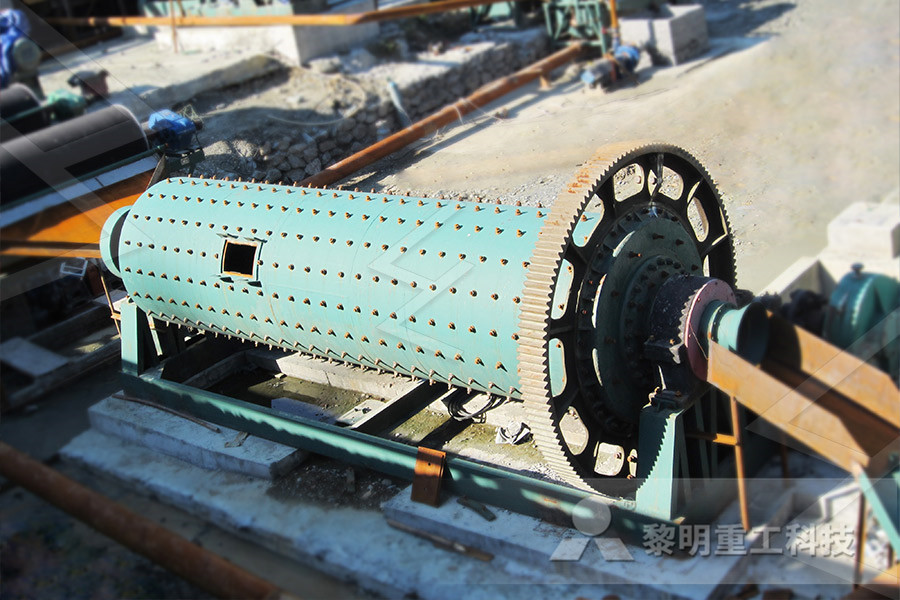

Failure analysis of a ball mill located in a cement’s production

2022年8月1日 The work herein presented analyses an existing failure in a ball mill of a cement production line The failure is recurrent and responsible for reducing the period 2020年2月1日 Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement In this work, the energy and exergy analyses of a cement Energy and exergy analyses for a cement ball mill of a new 2012年6月1日 Metal Powder Production by Grinding in Ball Mills D Karastoyanov V Monov T Penchev Materials Science 2022 7th International Conference on [PDF] Grinding in Ball Mills: Modeling and Process Control

Energy and exergy analyses for a cement ball mill of a new

2020年5月1日 In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and some measurements were carried out in an existing CBM in a 2023年3月21日 Ball mill processing 1 Introduction Concrete is a widely used building material because it is lowmaintenance, longlasting, and can be formed into any shape Processing of laboratory concrete demolition waste using ball mill 2021年6月11日 2021, 14, 3220 https://doi/ 103390/ma Abstract: In cement mills, ventilation is a critical key for maintaining temperature and material transportation Ventilation Prediction for an Industrial Cement Raw Ball

Ball milling as a mechanochemical technology for fabrication

2020年9月1日 Principles, mechanisms, and fundamentals for biochar ball milling are reviewed • Ball milling is an emerging technology for the production of engineered Abstract Cement sector in india is enjoyign success and capacity enhancement due to the rapidly growing demand in various sectors but at the same time a threat is approaching to cement industry that its input cost is increasing day by day like power cost, fuel cost, raw material cost Also cement is a highly energy consuming industryIndicate Contributions from Several Radial 2020年5月1日 The KMCC cement grinding system consists of a closed circuit ball mill, and it was supplied in 2006 by KHD Humboldt Wedag Company for guaranteed cement production of 210 t/h (ton/hour) The clinker grinding unit mainly consists of a ball mill and a dynamic separator that their technical information is illustrated in Table 1 Energy and exergy analyses for a cement ball mill of a new

Energy and exergy analyses for a cement ball mill of a new

2020年2月1日 Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and 2004年11月1日 The current world consumption of cement is about 15 billion tonnes per annum and it is increasing at about 1% per annum The electrical energy consumed in cement production is approximately 110 kWh/tonne, and around 40% of this energy is consumed for clinker grinding There is potential to optimise conventional cement clinker Cement grinding optimisation ScienceDirect2021年6月30日 The ballmilled rice husk slurry was prepared by ball milling for 20 min with 02 M NaOH Silica extraction yield and solid content in the continuous process depending on process time +2(PDF) TwoStage Continuous Process for the Extraction of

(PDF) Kaolinite obtained by ball milling as a potential

PDF On May 11, 2015, Rabah Hamzaoui and others published Kaolinite obtained by ball milling as a potential substituent for cement: mechanical performance effect on mortar based cement and milled 2021年3月12日 and cement Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1) The ball millBALL MILLS Ball mill optimisation holzinger 2021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550–600 million Review on vertical roller mill in cement industry its

(PDF) Grinding Media in Ball MillsA Review ResearchGate

2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their properties Also reviewed 2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials The overall grinding circuit efficiency and stability are EnergyEfficient Technologies in Cement Grinding 2021年7月27日 SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck Comminution is an important process in mineral processing, power plants, cement production and pharmaceutical industries It is costly and an inefficient process in terms of energy requirements and steel consumption related to grinding media andEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

Ball milling: a green technology for the

The effect of ball mill on the morphological and structural features of cellulose has been described by Okajima and coworkers 20 They treated microcrystalline cellulose derived from cotton linters in a planetary ball 2018年4月19日 The purpose of this study was to investigate the effect of working volume in the highenergy ballmilling process on the breakage characteristics (ie, particle size, morphology, and chemical composition) and adsorption performance of rice straw ash This study was conducted to confirm working volume issue since this parameter has Working Volume in HighEnergy BallMilling Process on• characteristics of the grinding media (mass, density, ball size distribution); • speed of rotation of the mill; • slurry density in case of wet grinding operation Quantitative estimations of these parameters can be found in [4, 5, 23] An important characteristic of an industrial ball mill is its production capacityGrinding in Ball Mills: Modeling and Process Control

Modeling and Optimization of Cement Raw Materials

This paper focuses on modelling and solving the ingredient ratio optimization problem in cement raw material blending process A general nonlinear timevarying (GNLTV) model is established for cement raw material blending process via considering chemical composition, feed flow fluctuation, and various craft and production constraints Different objective 2022年5月9日 Cement production is one of the most energyintensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production It is Modeling of energy consumption factors for an industrial cement of ball load composition, by varying the grinding media size distribution (eg alternatively by mixing four groups of 195, 38 mm; 195, 50 mm; 38, 50 mm and 195, 38, 50 mm), on the milling efficiency of a laboratory scale ball mill has been investigated in this article concerning ball number, total surface area, and ball weightEffect of grinding media on the milling efficiency of a

(PDF) Effect of ball milling process on the photocatalytic performance

2020年6月15日 When the ball milling speed, time, and material ratio were respectively 400 rpm, 10 h, 25:75, and then calcined at high temperature, after 2 h of irradiation under UV light, CdS/TiO2 composite 2020年6月1日 It is noted that the ball milling also enhanced the adsorption ability of biochars for other organic contaminants (eg, tetracycline and reactive red) and heavy metals (eg, Pb and Ni) ( Table 3)Ball milling as a mechanochemical technology for2014年2月21日 Mineral Processing –Milling Intermediate Technology Development Group 6 Figure 2: Rod Mill Ball Mills Description Ball mills are similar in concept to the rod mill but are charged with steel balls in place of the rods The mill consists of a cylindrical drum, sometimes tapered at one end, and usually hasMINERAL PROCESSING MILLING Internet Archive

Ball Milling an overview ScienceDirect Topics

Ball milling is a mechanical technique that is broadly used to grind powders into fine particles [134–141] The reactants are generally broken apart using solvent molecules in the traditional method; but in ball milling, reactants are broken by using mechanical forces The term mechanochemistry has been introduced very recently [142]2022年9月19日 The current production method of nanobiochar (NBC), an emerging, environmentally friendly nanocarbon material, is tedious and lengthy Therefore, in this study we aimed to improve the productivity of NBC via highenergy ball milling by manipulating the grinding media and processing time The particle size distribution of the resulting NBC Nanomaterials Free FullText HighEnergy Ball Milling for Ball Mill For instance, a ball mill, which is a powderprocessing technique involving deformation, cold welding, fracturing, and rewelding of powder particles, is used for mechanical alloying More recently they have become widely used for cement production They have lower specific energy consumption than ball mills and the separator, as Ball Mill an overview ScienceDirect Topics

(PDF) Analysis of the efficiency of the grinding process in

2016年1月1日 It was determined that, approximately 12% circuit capacity increase could be achieved in composite cement production when ball mill, ball mill filter and air classifier power consumptions were The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the prepBall milling: a green technology for the preparation and 2022年1月30日 A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, ie, 40, 254, and 127 mm and (ii) a mixed load of balls with varying sizes(PDF) Effect of Grinding Media Size on Ferronickel Slag Ball Milling

Manufacturing of Aluminum Flake Powder From Foil Scrap by Dry Ball

2000年4月1日 SPEX model 8000 12) ) Ball milling methods typically require lubricants and anticoagulants such as stearic or oleic acid and/or mineral spirits to control the shape and quality of the product 1971年8月17日 Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007 Portland cement accounts for 95 percent of the hydraulic cement production in the United States The balance of domestic cement production is primarily masonry cement Both of these116 Portland Cement Manufacturing US EPA2023年8月28日 Most popular application of ball milling is production of oxides of various metals for applications in sensor devices such as gas sensing Ball mill is crucial to numerous industries as an equipment for producing extremely crushed materials, eg cement, refractory materials, fertilizers, glass ceramic, ore dressing of ferrous as well as Module7 unit3 NSNT Module 7 Ballmilling

Ball milling as an important pretreatment technique in

2021年8月12日 It is the first and the most critical step that needs to be carefully selected and designed to overcome the constraints and improve the overall efficiency of bioethanol production In recent years, ball milling has been applied as an emerging technique to produce bioethanol from lignocellulosic biomass efficiently and in an environmentfriendly 2019年7月29日 14 Cement Mill and Bag House Clinker, along with additives, is ground in a cement mill The output of a cement mill is the final product viz Cement In a cement mill, there is a cylindrical shell lying horizontal which contains metallic balls and as it rotates, the crushing action of the balls helps in grinding the clinker to a fine powderball milling and production and pdf and concrete2018年12月9日 In a ball mill circuit, the "output" can be defined as the production rate of fines of the circuit As for any output, ball mill circuit output is a function of both its inputs and efficiencies There are two "inputs" to a ball mill circuit: the ore fed to the circuit and the power delivered by the grinding millMODULE #5: FUNCTIONAL PERFOMANCE OF BALL

Journal of Physics: Conference Series PAPER OPEN

conducted from a cement plant in Perak The milling facilities consist of a twocompartment airswept ball mill arranged in close circuit The first compartment of the open circuit mill contains balls ranges from 90mm to 30mm in diameter, while for the second compar tment contain 20mm ball Samples are taken from the twocompartment ball mill 2019年2月15日 Our results suggest that integrating an air classifier into an opencircuit ball mill can increase the production rate by 15% or increase the cementspecific surface area by 13% A singlecompartment mill entails a premilled feed for proper operation, whereas a twocompartment mill yields a finer cement product than a threecompartment millEffects of grinding aids on model parameters of a cement ball mill ball mill optimum speed filetype ball mill optimum speed filetype pdf ball mill optimum speed filetype pdf Effects of Ball Milling Conditions on Breakage R More InfoMore+ ; projGitHub

(PDF) Design of Threechamber Ball Mill ResearchGate

2021年1月1日 PDF Ball mill is a kind of raw material processing machinery which plays the role of grinding and production cost of the ball mill are comprehensively considered, so that it can achieve 2019年11月30日 The phase, morphological and functional groups characterization of CaO/CaCO3 from quail eggshell involve ball milling with variations of milling time at 3 h, 5 h, and 7 h and the calcination (PDF) Synthesis and Characterization of Calcium Oxide2021年11月15日 planetary ball mill gearing result in very high pulverization energy and therefore short grinding times [10,11] The type of planetary ball mill used in industry is the Retsch Planetary Ball mill PM100 [12] Furthermore, the principles of horizontal ball mill operations are limited regarding the fineness of the powder after millingOpen Access proceedings Journal of Physics: Conference

Indicate Contributions from Several Radial

Abstract Cement sector in india is enjoyign success and capacity enhancement due to the rapidly growing demand in various sectors but at the same time a threat is approaching to cement industry that its input cost is increasing day by day like power cost, fuel cost, raw material cost Also cement is a highly energy consuming industry2020年5月1日 The KMCC cement grinding system consists of a closed circuit ball mill, and it was supplied in 2006 by KHD Humboldt Wedag Company for guaranteed cement production of 210 t/h (ton/hour) The clinker grinding unit mainly consists of a ball mill and a dynamic separator that their technical information is illustrated in Table 1 Energy and exergy analyses for a cement ball mill of a new 2020年2月1日 Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and Energy and exergy analyses for a cement ball mill of a new

Cement grinding optimisation ScienceDirect

2004年11月1日 The current world consumption of cement is about 15 billion tonnes per annum and it is increasing at about 1% per annum The electrical energy consumed in cement production is approximately 110 kWh/tonne, and around 40% of this energy is consumed for clinker grinding There is potential to optimise conventional cement clinker 2021年6月30日 The ballmilled rice husk slurry was prepared by ball milling for 20 min with 02 M NaOH Silica extraction yield and solid content in the continuous process depending on process time +2(PDF) TwoStage Continuous Process for the Extraction ofPDF On May 11, 2015, Rabah Hamzaoui and others published Kaolinite obtained by ball milling as a potential substituent for cement: mechanical performance effect on mortar based cement and milled (PDF) Kaolinite obtained by ball milling as a potential

BALL MILLS Ball mill optimisation holzinger

2021年3月12日 and cement Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1) The ball mill2021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550–600 million Review on vertical roller mill in cement industry its 2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their properties Also reviewed (PDF) Grinding Media in Ball MillsA Review ResearchGate